FINNISH forestry equipment manufacturer Sampo-Rosenlew Oy, located in the city of Pori, presented a variety of new machines during the FinnMETKO 2018 forestry exhibition last autumn. Sampo unveiled a total of three new machines, more than doubling the company’s product portfolio (before this it had two forest machine models available). Both of the previous machines are suited mostly to thinning, the HR46x being a four-wheeled harvester and the FR28 being an eight-wheeled forwarder. In addition to these two models, Sampo now has the FR48 and FR68 forwarders, as well as the HR86 harvester. The latter two come out of the recent acquisition of former Finnish forestry machine manufacturer Logman, whereas the FR48 is a ‘genuine’ Sampo Rosenlew forwarder and also the first production-ready model of the three newcomers.

The FR68 and HR86 will be officially launched some time in mid 2019. Meanwhile, the FR48 has been making the rounds across Finland and nearby countries, with on-site test-drive events and deals closed at an exceptional rate.

BOGIES AND REAR IN FOCUS

Take a closer look at the FR48 and one of the first things that catches the eye is the almost identical look between it and the FR28. This is no secret, but rather a smart way to make the most out of the tried-and-tested parts of the FR28. The FR48 shares many common parts with its smaller sibling. The cab, engine, hydrostat, work hydraulics and middle joint all consist of familiar components. The differences hit in when you take a look at the rear frame, wheels, bogies, steering cylinders, and some under-the-hood flow control tweaks in the hydrostat system and crane hydraulics. The rear chassis frame is now extended by 1.2 metres and it has been slightly redesigned, reinforced and widened to handle the 14 tonnes of load and the bigger bogies. Still, it has the same basic form and profile as the rear chassis on the FR28. The balanced bogies are made by NAF from the Heavy Duty lineup, equipped with double rocker bearings and measured to carry the full total weight with ease. It’s not unfair to describe the bogies as ‘a bit overkill’ on a machine this size, but that doesn’t seem to cause any problems, even if they do add on more weight. This is because when it comes to forwarders, bogies are the parts most likely to wear out or break.

LARGER DIAMETER

The wheel size has increased from the FR28’s 710/40-22.5 to the FR48’s 710/4526.5. The larger wheel size has been one of the principles of design during the FR48 project, because Sampo Rosenlew customers asked for a machine with more wheel capacity to lower the ground pressure and improve terrainability. The FR48 was already on the drawing board during the evolution of the FR28, so the idea was clear for a while. But it was not until the Logman acquisition that the larger bogies became topical and plans were finalised to ensure the FR48 would also have heavy-duty bogies. As terrainability was the main reason for larger wheels and bogies, the increased load-carrying capacity came as an added bonus. Also, the new wheel and bogie construction allowed for the use of 900-mm-wide symmetrical tracks.

The balanced bogies tame down the machine’s behaviour and enhance its ability to move in tougher environments with uneven surfaces, soft soil or steep slopes. This is highlighted especially with the larger wheels, as the FR28 didn’t feature the balanced bogies. There has been an increase in operating weight due to the changes, however. Whereas the FR28 weighs in at 13,500 kg without tracks or chains, the FR48 tips the scales at a little over 17,000 kg.

UNLEASHING THE POTENTIAL

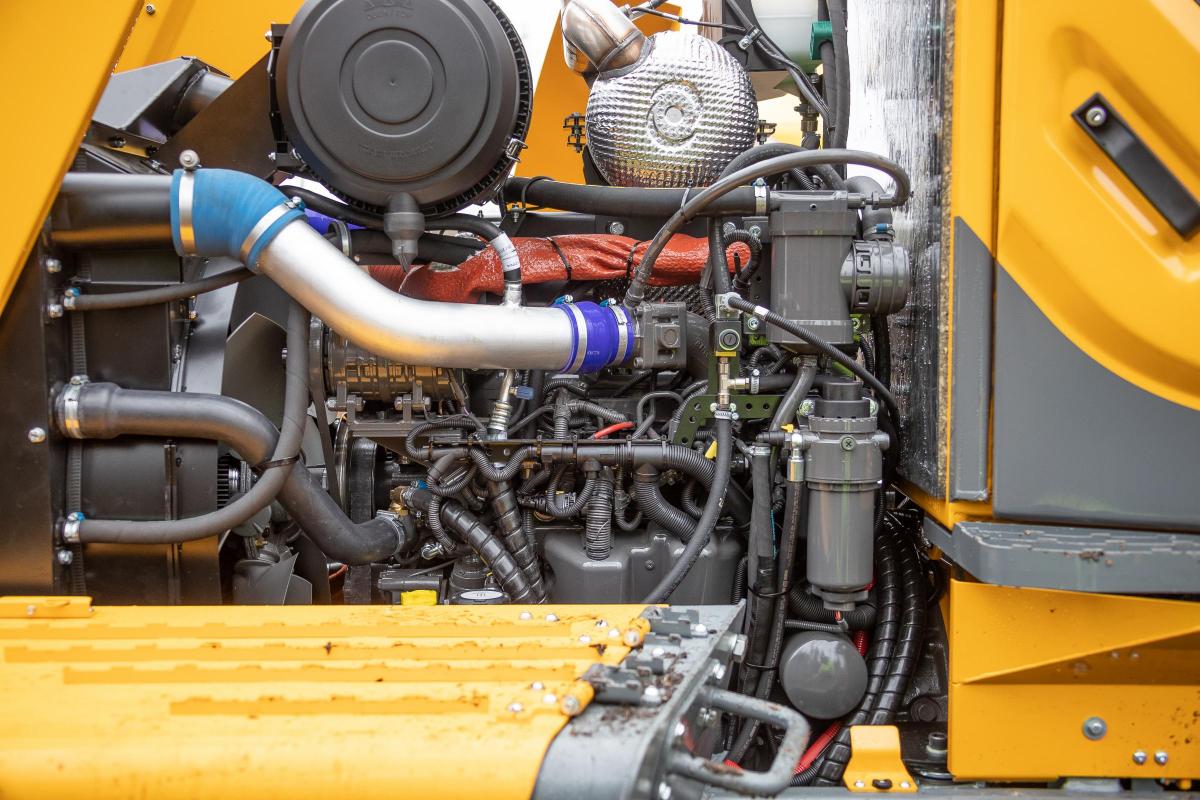

The FR28 was designed to be ready for this kind of evolution. Critical parts such as the middle joint and the hydrostat system by Bosch-Rexroth were upscaled for the future. Now, with the FR48 advancing to production, we can see the middle joint is still the same but the steering cylinders have been upgraded to provide more power and strength. The hydrostat is the same as in the FR28, but in the smaller machine it was programmed to deliver less power. Now the full effect is in play, producing 170 kN of traction force, compared to the FR28’s 130 kN.

The machine examined for this feature carries a Mesera 83F crane which is, in theory, similar to the Mesera 71F, but has a slight increase in lifting power. That change has been brought about by adding more pressure to the work hydraulic system. The engine is also the same Agco Power 49 AWF, with just a pinch of an increase to the kilowattage. It now boasts 127 kW, which must have something to do with the software management carried out due to the improvements on the driveline. Inside the cab, the only change is a larger Parker IQAN-display for the work hydraulics.

SIZING UP

Sampo-Rosenlew Oy has made a bold move to strengthen its foothold in a very competitive marketplace. The company seems to have listened to its current and potential future customers, resulting in a selection of larger machines. The FR28 was and still is a good companion for a smaller harvester, such as the HR46x. Still, bigger machines are now needed to team up with upcoming Sampo machines or other manufacturers’ medium and large machines, to work at late thinning or final felling sites.

This is what Sampo-Rosenlew Oy is now bringing in at the 14-tonne class. The long and comprehensive knowledge gained with the FR28 is clearly visible and the FR48 appears a fluent and rational step in the right direction. The driveline from the engine to the bogies is robust and hassle free, while the rest of the construction has been thoroughly proven, so the odds of failing with the new concept appear low.

There is, of course, the constant brand-related polemic going on between the die-hard supporters of different harvester and forwarder makes, and that ship turns slowly. But with some brave open-mindedness among the clientele, the Sampo Rosenlew FR48 might just give the others a run for their money in a new size class.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here